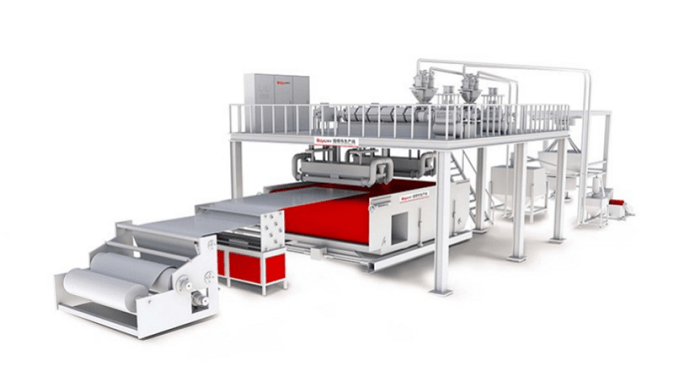

When you’re going to construct wpc production line, it’s a good idea to be sure that you have the resources and know-how to take on such a large project. This blog will provide some insights into the details of wpc production lines . Let’s learn more!

Introduction

Wood-plastic composites (WPCs) are composite materials made of wood fiber/wood flour and thermoplastic(s). In addition to wood fiber and plastic, WPCs can also contain other ligno-cellulosic and/or inorganic filler materials. WPCs are a subset of a larger category of materials called natural fiber plastic composites (NFPCs), which may contain no cellulose-based fibers.

WPC production line is an ideal equipment to produce WPC products. The main advantages of the WPC production line are as follows:

1.The WPC production line adopts special designed screw and barrel, die head, mold clamping device and injection system to ensure the optimum performance of the equipment.

2.The WPC production line has high degree of automation from material feeding to finished products outputting with stable performance and easy operation.

3.The WPC product made by the WPC production line is characterized by high density, high strength, good appearance, long service life, etc.

4.The whole process from material loading to finished products outputting can be completed in one stop, which greatly saves time and labor cost.

Types of WPC Production Line

There are three types of WPC production line:

Extrusion Line:

The extrusion line is the most common type of WPC production line. In this process, the material is melted and formed into a desired shape. This method is often used to create products such as decking, fencing, and siding.

Injection Line:

The injection line is less common than the extrusion line, but it is growing in popularity. In this process, the material is injected into a mold instead of being melted and formed. This method is often used to create products such as furniture and small appliances.

Compression Line:

The compression line is the least common type of WPC production line. In this process, the material is compressed into a desired shape. This method is often used to create products such as flooring and countertops.

Conclusion

A versatile and efficient method of making floors is the WPC production line. With this technology, you may create a vast variety of products in a wide variety of shapes, sizes, and colors. A WPC production line, such as Boyu Extruder, is something to consider, for instance, if you’re looking for a rapid and economical way to create floors.